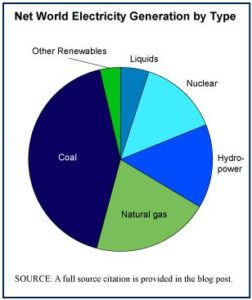

Most of the worlds continuous uninterruptable electricity generation is by coal, natural gas, hydropower, and nuclear.

Most of the worlds continuous uninterruptable electricity generation is by coal, natural gas, hydropower, and nuclear.

The primary usage of crude oil is for the manufacture of derivatives for thousands of products and fuels for transportation infrastructures. Tinkering with the supply chain of oil could impact the supply chain of thousands of products needed by current lifestyles and worldwide economies.

Of the 3 fossil fuels of coal, natural gas, and crude oil, it’s only coal and natural gas that are primarily used for the generation of continuous uninterruptible electricity.

- Natural Gas is often used for generation of continuous uninterruptible electricity at extremely low emissions.

- Coal is often used for generation of electricity, especially in poorer developing countries like China, India, and Africa where they need reliable, affordable, and abundant coal.

Crude oil is seldom used to generate electricity. When oil is used, three technologies are used to convert crude oil into electricity:

-

Conventional steam – Oil is burned to heat water to create steam to generate electricity.

- Combustion turbine – Oil is burned under pressure to produce hot exhaust gases which spin a turbine to generate electricity.

- Combined-cycle technology – Oil is first combusted in a combustion turbine, using the heated exhaust gases to generate electricity. After these exhaust gases are recovered, they heat water in a boiler, creating steam to drive a second turbine.

The primary usage of crude oil is for the manufacture of fuels for the many transportation infrastructures such as airlines, merchant ships, automobiles, trucks, military, the space program, and for the manufacturing of oil derivatives that are the basis of more than 6,000 products in our economy and lifestyles.

The short 100-seconds video illustrates how “Fossil Fuels are Essential to Modern Life”.

Case in point: Ridding America of Crude Oil will Eliminate the lubricants for Wind Turbines.

The average wind farm contains roughly 150 turbines. Each wind turbine needs 80 gallons of oil as lubricant, which is a PAO (polyalphaolefin) synthetic oil based on approximately 12,000 gallons of crude oil. The oil for each turbine needs to be replaced once a year.

Wind-turbine lubricants play a critical role in equipment operation, maintenance, and reliability of a wind farm. There are several lubrication points in a wind turbine, including gearbox, open gear, pitch gear, pitch bearing, rotor shaft, yaw bearing, yaw gear, hydraulic systems, and generator bearings. These points require various lubricants such as gear oils, hydraulic oils, and greases.

Gear oil is used in lubricating gearboxes; grease is used on the main rotor shaft bearing, yaw bearing, pitch drive gears, blade bearing and generator bearing. Hydraulic fluid is used in hydraulic systems for blade pitch control. Improper or insufficient lubrication can lead to significant maintenance and operations cost or equipment downtime.

It is estimated that 3,800+ turbines would be needed to power a city the size of New York. That’s over 304,000 gallons of refined oil for just one city.

Under the Biden climate plan, America will be discouraging U.S. energy independence, starting with suspending Federal Oil and Gas Permits, encouraging the shuttering, and halting of further fracking efforts in America, the cancellation of the Keystone XL pipeline, and banning importation of foreign crude oil.

Surprisingly, Biden must be oblivious to the consequences of his plan as efforts to cease the use of oil could be the greatest threat to civilization, not climate change.

Without any crude oil to manufacture, elimination of the supply chain to the 129 operating refineries in the U.S. would eliminate that manufacturing sector. Without that American refining sector, the demands for the fuels and products that are the basis of our lifestyles and economy would need to be met by foreign refiners exporting to the USA.

Without the supply chain of crude oil, not only is the refining industry history, but the domino effects are the destructive impacts on the medical, food supply, electronics, and communications industries as they are all totally dependent on the products made from oil derivatives manufactured from crude oil. Any grade school educated kid can understand that breezes and sunshine, can only make weather-dependent intermittent electricity.

By picking wind and solar as the green solution to electricity generation, the short 3-minute video from Planet of the Humans illustrates the “blood minerals” needed for green energy that’s discussed in the 2022 Pulitzer Prize nominated book “Clean Energy Exploitations – Helping Citizens Understand the Environmental and Humanity Abuses That Support Clean Energy.

Rather than picking winners and losers for electricity generation, the world should focus on the proper mix of electricity generation via coal, natural gas, hydropower, nuclear, and the renewables of breezes and sunshine, and not tinker with the supply chain of crude oil as it is seldom used for electricity generating.

While renewables continue to underperform in the generation of electricity, the innocent bystander of crude oil that is seldom used for electricity, continues to be targeted for elimination along with coal and natural gas. We must be reminded ourselves that crude oil provides societies and economies with the supply chain of manufactured fuels for the many transportation infrastructures, and the manufacturing of oil derivatives, that are the foundation of thousands of products that are the basis of lifestyles.

Imagine the calculation for every city across the nation, large and small, to find the grand total of yearly oil consumption from “clean” energy.

Where do you think all that oil is going to come from? Not to mention the fact that the large equipment needed to build these wind farms run on petroleum. As well as the equipment required for installation, service, maintenance, and eventual removal. And just exactly how eco-friendly is wind energy anyway?

Each turbine requires a footprint of 1.5 acres, so a wind farm of 150 turbines needs 225 acres. To power a city, the size of NYC you’d need 57,000 acres; and who knows the astronomical amount of land you would need to power the entire US. All of which would have to be clear-cut land because trees create a barrier & turbulence that interferes with the 20 mph-sustained wind velocity necessary for the turbine to work properly (also keep in mind that not all states are suitable for such sustained winds).

Regarding blade disposal: the lifespan of a modern, top quality, highly efficient wind turbine is 20 years. After that, they cannot economically be reused, refurbished, reduced, repurposed, or recycled, so they are transported to special landfills. And they are already running out of these special landfill spaces. Those blades are anywhere from 120 ft. to over 200 ft. long, with three per turbine. Since only 7% of the nation currently being supplied with wind energy, imagine if we had the other 93% of the nation on the wind grid; 20 years from now we’d have to assign many new landfills for those unusable blades. Then 20 years after that, and 20 years after that, and so on

(May I suggest Washington, D.C. as a landfill site? That is where most useless things seem to gravitate.)

We also lose about 500,000 birds’ year from wind turbine blade collisions; most of which are endangered hawks, falcons, owls, geese, ducks, and eagles.

Apparently smaller birds are more agile and able to dart and dodge out of the way of the spinning blades, whereas the larger soaring birds aren’t so lucky.

Welcome To the Wind Turbine Graveyard near Casper, Wyoming. Here is your “clean energy detritus!”

Note the size of the bulldozer burying the blades, in comparison to the blade size. The wind turbine graveyard stretches a hundred meters {328 feet} from a bend in the North Platte River in Casper, Wyoming. California, Colorado, Kansas, and many other states are doing the same thing, as the fiberglass blades will never deteriorate {not biodegradable}. Between 9/2020 and 3/2021 this will become the final resting place for 1,000 fiberglass turbine blades.

These blades, which have reached the end of their 20-year working lives, come from three wind farms in the northwestern US state. Each will be cut into three pieces, then the pieces will be stacked and buried.

Turbines from the first great 1990s wave of wind power are reaching the end of their life expectancy today. About two Gigawatts worth of turbines will be refitted in 2019 and 2020. And disposing of them in an environmentally friendly way is a growing problem.

This cost taxpayers $200,000 or more per unit, or 200 million total for the 1000 blades, to have them transported and decommissioned.